Digitized Lab Inventory Management: What Benefits Make It Significant?

Editor’s note: In the article, Alena explains how lab inventory management software helps optimize crucial laboratory operations. If you’re looking to get more details about the software features that will bring the best return on investment in your specific situation, ScienceSoft’s consultants are ready to help. Our expertise is founded on 20 years of experience in building custom solutions for healthcare providers, diagnostic centers, and research laboratories.

What happens to day-to-day lab operations when there is no effective automation in inventory management? Merck’s Connected Lab shared their two survey results [1, 2], which paint a vivid picture of such a scenario:

- Lab scientists spend up to 25% of their working hours on keeping manual inventory records.

- 90% of the time, they struggle to find the required consumables because the inventory records are inconsistent or outdated.

- It can take up to 50 minutes just to find a sample.

- In 24% of the labs surveyed, at least every tenth experiment is canceled due to a sudden reagent shortage.

- 17% of respondents lose at least a tenth of their inventory monthly due to spoilage and expiration.

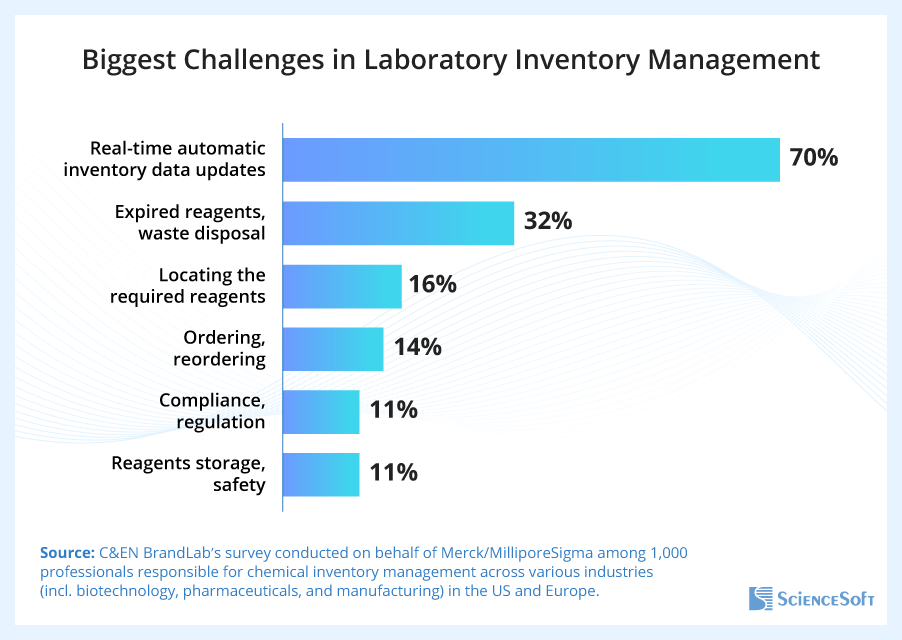

Most respondents (70%) agreed that their biggest problem is the lack of real-time automatic updates on the status and location of the reagents needed. The diagram below lists their other pressing issues related to inventory management.

Benefits the Lab Gets by Using Inventory Management Software

Effective software that automates lab inventory management can bring multiple benefits to laboratories. Let’s examine the most important ones and explore the features that make them possible.

Reduced manual workload and data entry errors

Lab inventory software can be integrated with handheld barcode readers, RFID (radio-frequency identification) readers, or QR-code scanners on mobile devices. Then, when lab supplies arrive, instead of entering the data manually, lab staff can simply scan their barcodes, QR codes, or RFID tags, and the system will automatically add all the details to the laboratory information system, including item name, batch, vendor, expiry date, etc. This can save lab staff as much as 40% of their working hours, according to some of our clients. Automated data entry can also eliminate human errors and thus significantly improve data accuracy.

Real-time inventory visibility

Since lab inventory management solutions typically store data in a secure, HIPAA-compliant cloud, any lab department can access inventory data at any time, regardless of their location. With such a solution for inventory management laboratory staff can locate any reagents or samples with just a few clicks, using visual dashboards that display the exact location, quantity, and status of each item. Moreover, the system tracks inventory in real time, meaning that if any reagents are used, moved, or opened, this will immediately show up on all other users' dashboards. That way, the staff always has accurate, up-to-date data at all times.

Reduced supply wastage

An inventory management system tracks expiration and package opening dates and sends staff automated notifications about reagents close to expiring. It can also ensure that such reagents are used first by highlighting them for lab staff when they are about to retrieve a reagent. Through integration with IoT temperature and humidity sensors, the software can also monitor storage conditions for sensitive reagents and biological samples. Based on the findings, it can automatically generate storage condition reports and alert lab staff when consumables are stored incorrectly to prevent spoilage. Merck’s survey found these controls cut reagent waste costs by up to 75%.

Prevented stock-outs and overstocking

A digital lab inventory system allows you to set stock thresholds that trigger an alert when supply levels drop too low. As a more advanced approach to inventory management in laboratory, I would suggest integrating a data analytics module that monitors reagent usage trends to forecast consumption. An inventory management software could also include an AI engine, which can recommend the best stock levels and resupply schedules for each inventory item to prevent both shortages and excess that could lead to spoilage losses. To learn more, take a look at the guide on inventory optimization using data science prepared by Alex Bekker, Principal Architect, AI & Data Management Expert at ScienceSoft.

Automated procurement management and minimized procurement costs

An AI engine can also handle procurement planning using demand forecasts and even place restocking orders automatically if the software is integrated with supplier systems. A recent study indicates that ML/AI-based tools forecast inventory demand with more than 80% accuracy and lower inventory costs by about 25% compared to other leading inventory management methods. Moreover, integration with the lab’s accounting systems enables an AI engine to track per-unit costs, analyze procurement spend by supplier and period, and suggest cheaper sourcing options.

Reduced downtime and extended equipment lifespan

An inventory management app can track instrument hours and automatically schedule preventive maintenance and calibrations. When enhanced with AI and IoT equipment sensors, it can also provide predictive maintenance by analyzing real-time equipment performance metrics and usage patterns to identify early signs of wear or malfunction and forecast when maintenance is needed. Then, it can automatically adjust the maintenance schedule and manage spare parts inventory accordingly. This proactive approach helps prevent costly equipment failures, minimizes operational interruptions, and keeps equipment performing at its optimal level without requiring extra staff time.

“The feature helped us to cut downtime costs substantially,” says one of the labs ScienceSoft worked with.

Improved audit readiness and regulatory compliance

For R&D laboratories in the biotech and pharmaceutical sectors, meeting regulatory standards is a must. The FDA (US Food and Drug Administration), EMA (European Medicines Agency), and other regulators demand full traceability of lab supplies and inventory. Digital inventory management systems handle this automatically, logging quantity, location, expiry, supplier, storage conditions, every single use or movement, and disposal of each consumable. This ensures audit readiness and protects against fines that could take up 30% of company profits.

Reported Outcomes of Implementing a Laboratory Inventory Management Solution

Here is a real-life example that gives an idea about the value inventory management solutions can bring to laboratory settings.

A German medical center, Klinikum Frankfurt Höchst, which serves more than 116,000 patients and performs about 3.6 million tests per year, implemented an inventory management solution to get rid of inefficient manual processes in its labs. This cloud-based system utilizes RFID technology for real-time inventory tracking, automatically generates resupply orders, sends expiration alerts, and provides full visibility into the lab’s consumables through user dashboards.

After implementing the solution, the organization reported impressive results:

- 35% reduction in lab staff time spent on inventory management tasks.

- Elimination of emergency orders and decrease in routing order time from 25 to 5 minutes, resulting in up to 4 work hours saved weekly.

- Optimized stock levels and reduced costs achieved through cutting excess supplies and minimizing waste caused by reagent expiration.

- Enhanced compliance due to better documentation and inventory traceability.

Time to Invest in Your Lab’s Efficiency!

I believe lab inventory management software is a core foundation for automating and optimizing lab operations. Automated data entry, real-time inventory monitoring, efficient expiry tracking, and automatic handling of compliance documentation — all of these capabilities have already become standard in modern labs. And increasingly, intelligent demand forecasting, predictive maintenance for lab equipment, and supply automation with AI are being added to this standard toolkit.